Well Testing & TCP Services

TCP Perforating Service

PetroFine Tubing Conveyed Perforating (TCP) equipment delivers high performance charges for demanding perforating operations in plug and abandonment (P&A) and completions.

Perforating is essential in delivering wells, improving well performance, Plug and Abandonment (P&A), and remedial work during the lifetime of a well. PetroFine provides various shaped charges including patented liner material technology, which ensures cleaner perforation tunnels for increased well productivity. Archer`s extensive P&A experience, combined with our tailor-made perforating systems, ensures time efficient and optimized P&A operations.

Benefits

– Deeper and cleaner perforation tunnels for

increased well productivity

– Excellent track record

– High performance punchers and squeeze gun systems

for controlled penetration length and casing hole size

Applications

– Plug & Abandonment (P&A)

– Well completions

– Formation testing

– Remedial work

Features

– Can deliver from 0 to 360 degree phasing — Produce optimal casing entrance hole diameter

– Controlled perforation of single or multiple casings

– Can perforate between casings to remove sustained pressures

– Gun outer diameter (OD) range from 2” to 7”, and shot density of 1 shot per foot (spf) to 36 spf

Associated TCP Services

In addition to standard and specialized Tubing Conveyed Perforating (TCP) services, we offer associated services, including:

– Punching

– Explosive and electro-mechanical pipe-cutting

– Pyrotechnic and plug setting horizontal pump-down “plug and shoot”

– Coil tubing perforating

– Wireline perforating

Surface Well Testing

Surface well testing is the only technique available today that assesses the true reservoir potential at full scale under dynamic conditions. It validates well performance during cleanup and commissioning and provides reservoir monitoring for better field management.

With a wide variety of surface well testing equipment available for exploration and appraisal operations through development and production campaigns, PetroFine has the technology and the expertise to acquire accurate and reliable surface well test measurements during each phase of the field development while meeting the most stringent HSE regulations in complex conditions and challenging environments.

Surface Well Test equipments:

When performing well tests, the following items must be addressed:

• requirements of dynamic conditions

• type and layout of surface testing equipment

• equipment needed to collect samples at the surface

• safety requirement

Surface testing equipment must safely and reliably perform a wide range of functions:

• Quickly control pressure and flow rates at the surface and shut in the well.

• Separate the effluent into three separate fluids (oil, gas and water), accurately meter the fluids, collect and separate solids as applicable.

• Collect surface samples.

• Dispose of the resulting fluids in an environmentally safe manner.

Standard Set of Equipments:

1- Flowhead

2- Separator

3- Safety Valve

4- Gauge or Surge Tank

5- Choke Manifold

6- Transfer Pump

7- Emergency Shutdown (ESD) System

8- Oil & Gas Manifold

9- Heat Exchange

10- Burners & Booms

Downhole memory gauges

& Multiphase flow meter ( VX )

– Run down Hole different Memory gauges ( uni -gauges & Signature) to Acquire down hole data for data interpretation

– Operate Vx technology (Multiphase meter) to measure (Oil, Gas and Water) rates while production and during test.

Memory Gauges Types:

1- UNIGAGE-CQG

WCQR 16 kpsi / 177°C Schlumberger Compensated Quartz sensor

2- UNIGAGE-Quartz

WTQR 18 kpsi / 177°C Schlumberger customized Quartz dyne sensor

3- Unigauge Kit and batteries

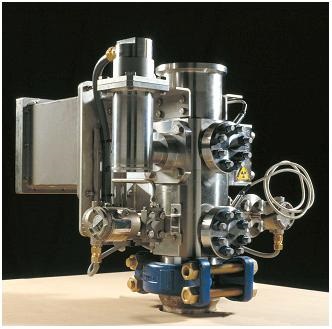

MPFM – Multiphase Flow Meters:

PetroFine offers Multiphase Flow Meters (MPFM) as a complementary service to existing portable well test separators -without the requirement for phase separation.

Measurement can be made at wellhead or line conditions, allowing process fluids to be returned to the production process, without pressure reduction.

Typical applications include exploration & appraisal, commissioning & clean up and routine production well testing operations.

Benefits of the portable well testing MPFM include:

■ Small and compact foot print

■ Instantaneous measurement of rate and fraction

■ A wide operating range up to 98% GVF

■ Non-intrusive measurement

■ Real-time well site commissioning, data processing and diagnostics

Well site operation of the MPFM is supported with Expro’s proven well site PVT sampling and analysis products and services.

Data Acquisition

Data acquisition is one of the most important objectives of well testing. While the equipment used to perform a well test has improved technologically over the years, the need to acquire data remains the same.

PetroFine has continuous plan to develop its data acquisition portfolio to ensure reliability, accuracy, and easy access to information as it is being measured.